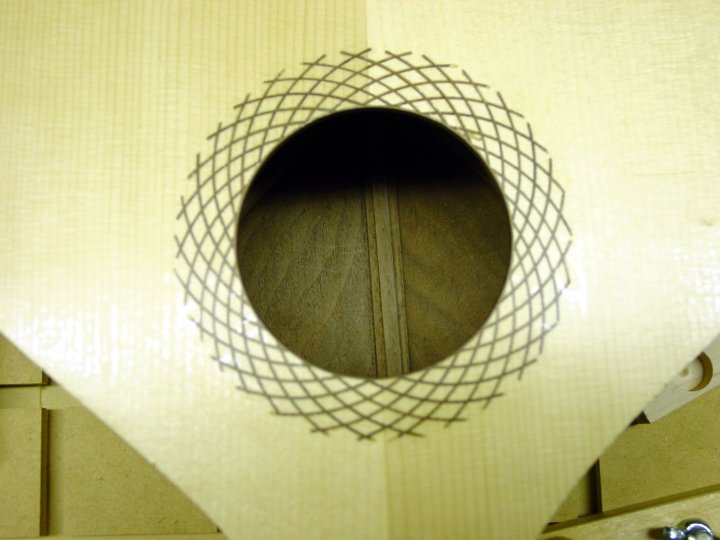

Several asked how Dan Fobert accomplished his spyrograph-looking rosette that was pictured a couple of weeks ago. I was looking at the LINT site and saw that Dan had done a pictorial of this very thing. It is indeed a spyrograph approach, and each of the lines is inlaid, not drawn. Here's the finished rosette:

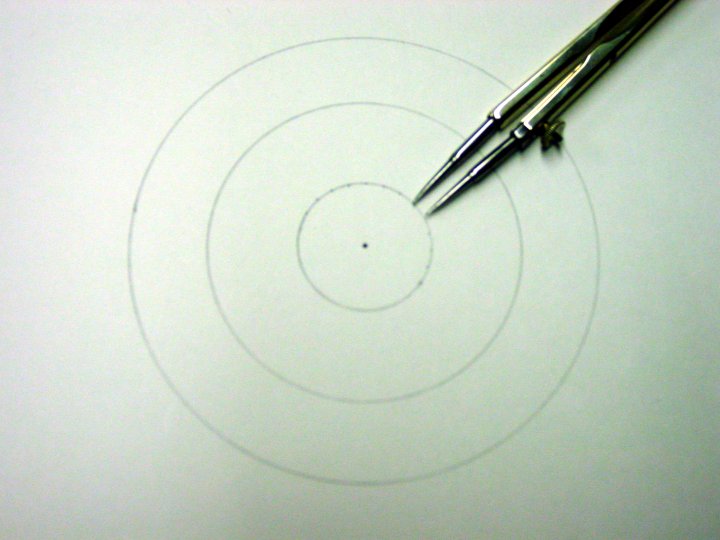

He starts by drawing concentric circles that define the inner and outer parameters of the rosette. Note the 1" inner circle with the pivot points drawn in at 4mm intervals:

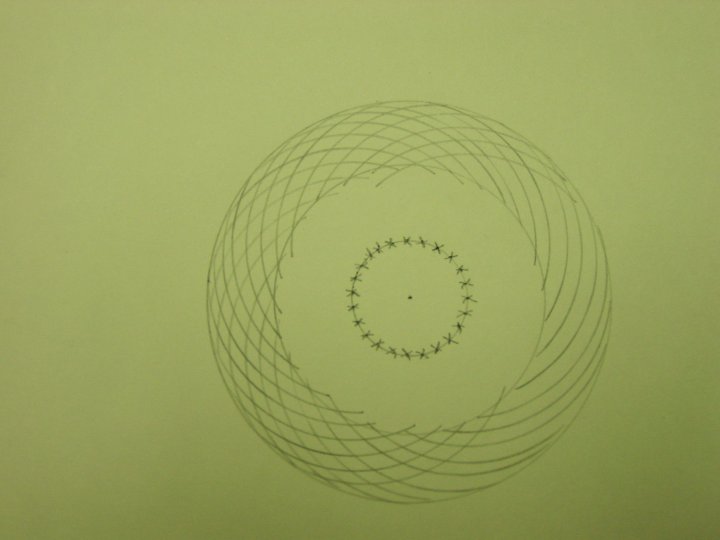

Next is a drawing-in of the router path based on those points, which shows what the finished rosette will look like:

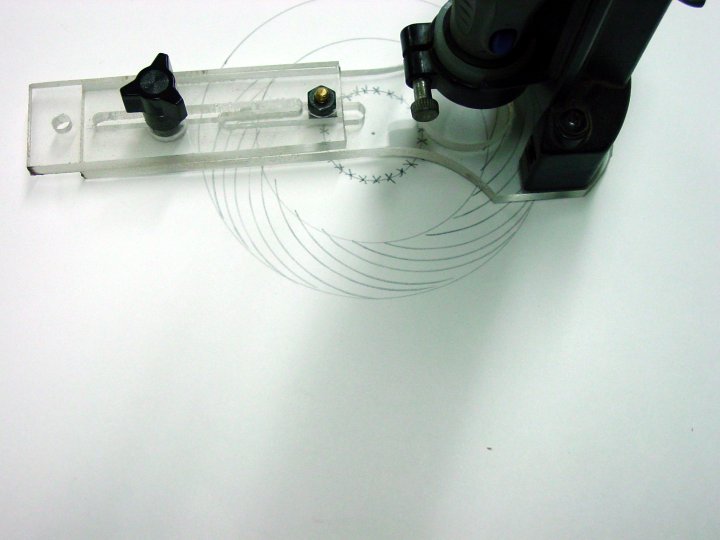

And finally the routing:

Dan said that you could easily rout an outer circle to further define the outer circumfrence of the rosette, and tie up any "loose ends". That might give a little cleaner look, but then you might loose some of the spyrograph effect. He did use an inner band, which hides the backing glued to the underside of the top. Here's a shot of the finished instrument, an Irish bouzouki:

Hope you enjoy this, and if you try one, let Dan know you appreciate his sharing this info.

Steve